Just as crucial as choosing the ideal tile for the project is choosing the proper tile adhesive. The adhesive’s task is to secure the tile’s base to the setting bed, a flat surface. Adhesives have significantly improved over the past few years, making it simpler for amateurs to lay tile themselves rather than hiring a professional. The most popular materials are organic mastics and thin-set mortar, though latex, acrylic, and epoxy are occasionally employed.

Considering the type of installation required for the project is the first step in selecting a tile adhesive. In addition to other factors, a tile installer should think about whether the tile will be applied indoors or outside, to the wall or the floor, or in a damp or dry environment. The installer should also think about the setting bed that will be utilised, whether it is plasterboard, concrete, plywood, or backerboard.

One of the most widely used categories of adhesives is organic mastics. They are frequently bought since they don’t need to be mixed and because they keep wall tiles from sliding. However, those who use them need to be cautious about where the tiles will be installed because this kind of glue shouldn’t be used for tiles installed outside the home or in hot climates.

( High-Performance Tile Adhesive Manufacturer )

Thin-set mortar is the second most popular kind. It is often mixed by the person laying the tile, and it gives greater flexibility and a stronger bonding strength than organic mastics. A thin layer of this adhesive—typically no thicker than 0.1875 inch (4.76 mm)—is applied to the tile. It is simple to locate he ideal thin-set mortar for practically any work because they come in a huge variety.

A type of thin-set mortar is mortar that is water-mixed or dry-set. It consists of Portland cement, sand, and a substance that encourages water retention. This mortar is advantageous since it enables the glue to hydrate; it is simply blended with water. In the tile industry, it is one of the most popular adhesives.

Selecting the right type should be simple if you follow the general tile adhesive rules and ask lots of questions at the home improvement store. Prior to making a purchase, buyers should read the directions for each adhesive. Each firm may have a variety of adhesives, some of which may attach more strongly, dry more quickly, be more water resistant, and shrink less than others.

( We are India’s No.1 Tile Adhesive Manufacturer in India )

Difference between Tile Adhesive and Cement:

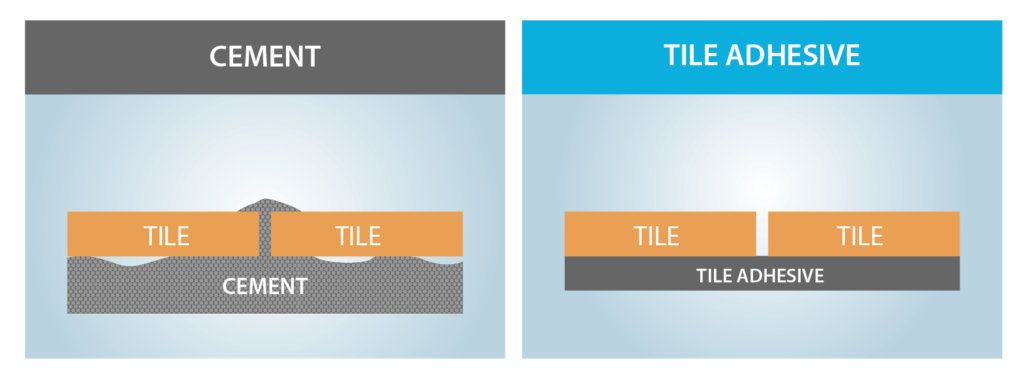

In the past, cement mortar and cement slurry were employed to attach tiles. Because cement dries quickly, applying it would leave empty gaps underneath the tile’s surface, eventually causing cracked and chipped tiles in a noticeably short period of time. Natural sand supplies came to the rescue before applying cement.

Less material is needed when using tile adhesive to lay tiles with a notched trowel. Because the adhesive layer is thinner than the sand-cement mix, the load on the building structure is reduced. The main purpose of tile adhesives is to quickly and easily bond tiles to surfaces. Its workability is enhanced by the use of polymers and graded aggregates, which also add superior adhesive and water-proofing qualities. In terms of bonding strength, it offers longevity and is superior than cement mortar mix.

( CHEMAX – Tile Adhesive Chemical Exporters )