Elevating Construction Excellence: The Role of Tile Adhesive Manufacturer

The stability, longevity, and general visual appeal of tiles are all enhanced by the use of tile adhesive during installation. We will examine the significant contribution tile adhesive producers make to the building sector in this blog post. We explore the fundamental elements that make tile adhesive producers a crucial ally in attaining construction perfection, from the creation of superior adhesives to their influence on the installation procedure.

Innovating Formulations for Superior Performance

Manufacturers of tile adhesive are at the forefront of innovation, continuously creating and improving formulations to satisfy the changing needs of the building sector. They engineer adhesives with extraordinary bonding strength, flexibility, and durability through rigorous research and development. These cutting-edge formulas guarantee that tiles stay firmly in place even in high-stress situations or locations that are vulnerable to changes in moisture or temperature. Tile adhesive producers make items that not only satisfy customers but also surpass strict quality standards by utilizing state-of-the-art technology and components.

Tailoring Solutions for Diverse Applications

Customized solutions are crucial for tile adhesive producers, as they recognize that every building project has distinct needs. They provide a large selection of adhesives appropriate for various substrates, tile kinds, and installation techniques. Glass, porcelain, ceramic, or natural stone tiles—manufacturers create adhesives with certain qualities to meet the needs of each application. This guarantees the best possible compatibility and adherence, making tile installations aesthetically pleasing and long-lasting.

Ensuring Efficiency and Ease of Application

Manufacturers of tile adhesive work to improve the installation procedure in addition to product performance. They create adhesives that are simple to work with, mix, and apply, increasing productivity and cutting down on installation time. Manufacturers allow installers to work as quickly as possible without sacrificing the integrity of the installation by offering adhesives with longer open durations or quick curing qualities. These factors help to make the tile installation process more efficient and effective, which benefits project timelines and contractors alike.

Emphasizing Quality and Reliability

When it comes to tile adhesives, dependability is crucial, and trustworthy producers place a high value on the quality of their goods. They guarantee consistent performance, batch after batch, through stringent testing and quality control procedures. By following industry certifications and standards like ANSI or ISO, these producers give their clients peace of mind by guaranteeing the dependability and toughness of their tile adhesives. This dedication to quality reduces the possibility of problems in the future and protects the integrity of tile installations, which saves money and time on building projects.

Conclusion:

Manufacturers of tile adhesive are essential to the construction sector because they offer specialized, dependable, and creative solutions for tile installations. They consistently raise the bar in terms of product performance, application simplicity, and overall construction perfection thanks to their dedication to research and development. Selecting a reliable supplier of tile adhesive guarantees that your tile installations will be long-lasting and visually appealing.

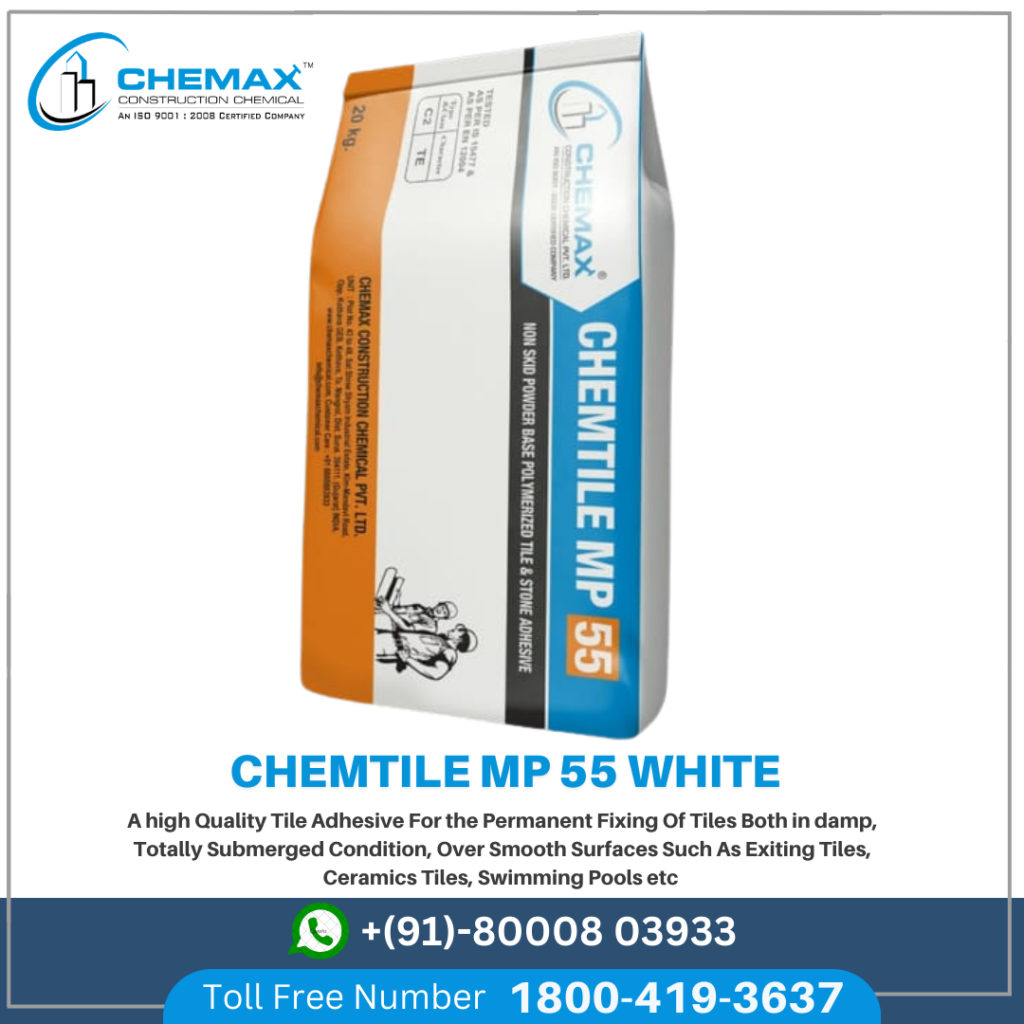

How To Apply CHEMTILE MP 55 Chemicals Step By Step Details:

Surface Preparation: Prior to applying CHEMTILE MP55, all surfaces must be sound and spotless. Using the appropriate degreaser, all oil or grease residue needs to be eliminated. It is necessary to physically remove any loose mortar, paint, wallpaper, and other materials. When it comes to cementation surfaces, the application regions need to be completely soaked with water in order to get a saturated, dry state. It is not necessary to moisten the substrate beforehand with water when the surface is smooth.

Mixing: Three to one by volume or four to one by weight is the recommended ratio for mixing CHEMTILE MP55 with water. Add the powder to the water while mixing to prevent lumps from forming. For mixing, a slow-speed drill equipped with an appropriate mixing paddle is advised. If little quantities need to be blended, hand mixing is an additional option. (Note: Using cooled water in extremely hot weather will lengthen the CHEMTILE MP55’s open period.)

Application: A homogeneous thickness of 2 mm to 12 mm (minimum to maximum) is achieved by spreading CHEMTILE MP55 on the substrate. After that, a notched trowel is used to comb this horizontally. Next, using a twisting motion to ensure adequate contact with the mortar, the tiles are firmly inserted into the adhesive bed.

Finishing: Before the material sets, remove any excess with a moist towel. Grouting joints using CHEMAX JOINT Twenty-four hours after the tiles are fixed, grout can be applied.

Also Read :

- Tile Adhesive Manufacturers India

- Stone Adhesive Supplier Pune

- Stone Adhesive Chemical Mumbai

- Tile Adhesive Chemical Manufacturer