Tile Adhesive For Wall & Floor

Quality Tile Adhesive For Wall & Floor

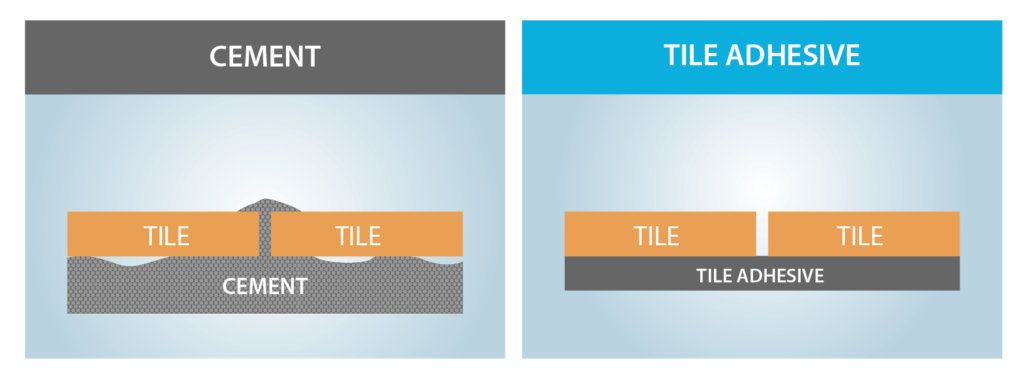

Every construction needs flooring since it enhances the beauty and appeal of each space and, ultimately, your house. Due to their high level of durability and affordability, tiles are the most popular flooring material. A unique kind of glue called tile adhesive is used to fix tiles all throughout the house. Tile adhesive is a pre-made mixture that includes Portland cement, polymers like epoxy, and certain aggregate particles. It also contains some additives to enhance its tile-laying properties.

( Tile Adhesive Chemical Manufacturer )

Tiles can be fixed to walls, floors, swimming pools, and other surfaces with a variety of substrates, including cement, wood, glass, and more, using tile adhesives. They generally consist of polymer, epoxy, and cement. We have made an effort to provide a quick overview of tile adhesive in this article, including some of the different varieties that are available.

Because it is a flexible material, tile adhesive, moisture and temperature fluctuations do not cause it to shrink or crack. To stop tiles from crazing and shedding, use tile adhesive. Since ready-made bags are readily available and only water needs to be combined, using a tile adhesive is relatively simple. There are now also pre-mixed tile adhesives on the market. They are also utilized to stop or remedy water seepage beneath the tiles.

Tile Adhesives for Tiles Flooring:

For brand-new tile flooring, polymer-modified cement-based tile adhesives are typically utilised. These adhesives come in powder form and must first be mixed with water before being applied. Compared to regular cement-sand mortar, they provide more strength. Additionally, they have waterproof qualities and can be applied in damp locations like bathrooms, kitchens, swimming pools, etc.

For brand-new tile flooring, polymer-modified cement-based tile adhesives are typically utilised. These adhesives come in powder form and must first be mixed with water before being applied. Compared to regular cement-sand mortar, they provide more strength. Additionally, they have waterproof qualities and can be applied in damp locations like bathrooms, kitchens, swimming pools, etc. To increase its adhesive qualities, other polymers are used, including acrylic, latex, epoxy, etc.

Polymer-modified cement-based tile adhesives are frequently used for brand-new tile flooring. These adhesives are available in powder form, and before use, they must be combined with water. They are more durable than typical cement-sand mortar. They can also be used in wet areas like bathrooms, kitchens, swimming pools, etc. due to their waterproof characteristics. Other polymers, such as acrylic, latex, epoxy, etc., are employed to boost its adhesive properties.

Acrylic makes tile adhesive moisture-resistant. Typically, it is employed to repair little tiles. Ceramic tiles, vitrified tiles, natural stone tiles, etc. can all be easily repaired.

Epoxy helps to increase the durability and tensile strength of adhesives. Epoxy modified adhesives can be used both internally and externally because they are resistant to oils, water, mild acids, weak alkalis, and the majority of solvents. Epoxy is the most expensive and effective tile adhesive. Industrial applications for epoxy modified adhesives include bonding corrosion- and chemical-resistant tiles.

Why CHEMAX ?

Here, Chemax provides a variety of construction chemical products for sale throughout India, including concrete additives, surface treatments, grout and industrial flooring products, structural repair products, adhesive and bonding agents for joining building materials and specialty associated products.

- Top Tile Adhesive Manufacturer

- Tile Adhesive Supplier India

- Quality Tile Adhesive Manufacturer India

- Tile Adhesive Exporter Mumbai

- Tile Adhesive Pune

- Tile Adhesive Supplier Pune