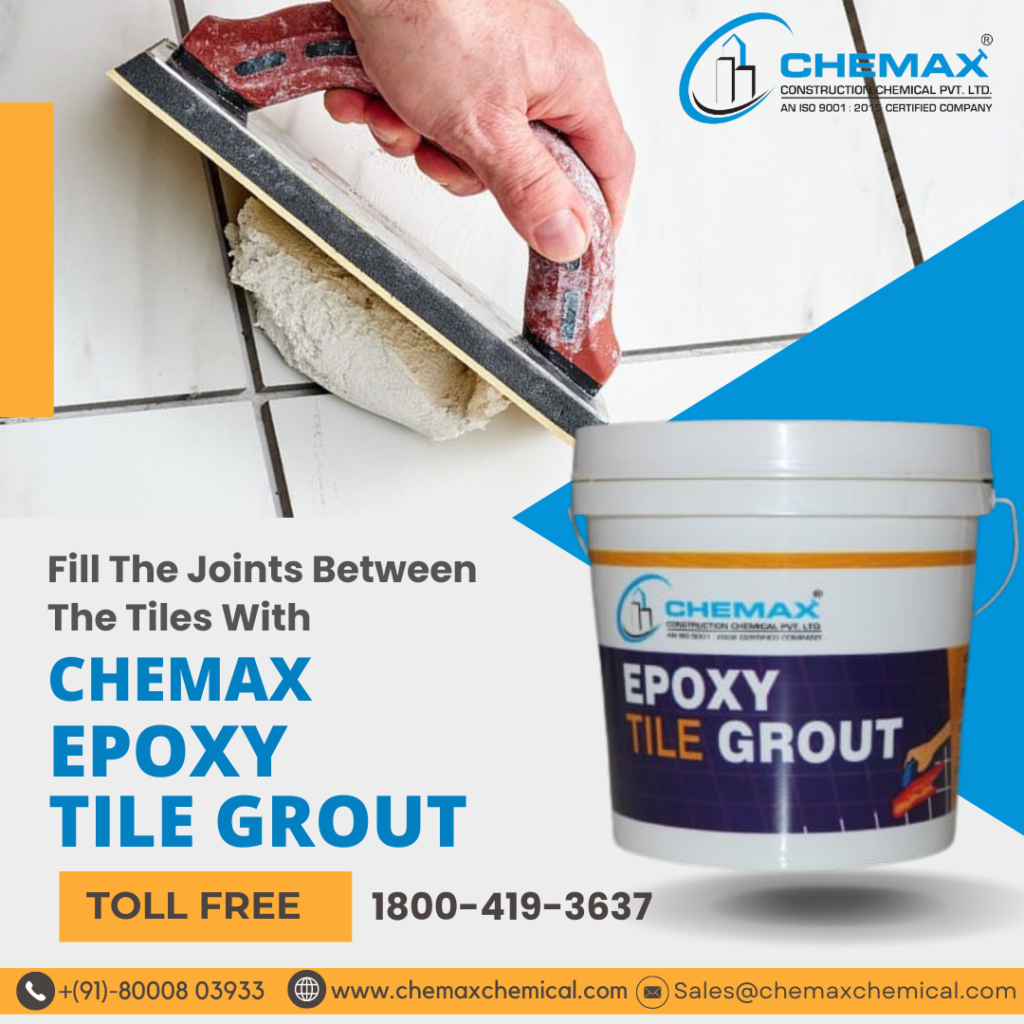

premium Quality Epoxy Grout Manufacturer

Epoxy resins are used to make this sort of grout. When a high level of strength and waterproofing is needed, this grout is employed in tile applications because it is robust, long-lasting, and waterproof.

Epoxy tile grout is suitable for both indoor and outdoor use and is mold and mildew resistant. For tile applications, epoxy grout is a good option if you’re searching for a grout that is both waterproof and strong.

We will go over all you need to know about epoxy tile grout in this blog post, including its advantages and disadvantages, to help you decide if using an epoxy tile solution is the best option for your tiling job. Investigate Somany’s selection of Ezy Grout epoxy grouts to discover more about epoxy grouts.

The advantages of epoxy grout for tiles One kind of grout that is created with epoxy resin is epoxy tile grout. Because it offers so many advantages over conventional grout, it is employed in its stead and is growing in popularity.

Some of the benefits of epoxy tile grout include:

- Greater durability: Compared to regular grout, epoxy tile grout is far more resilient and can endure for many years before needing to be changed.

- Stain-resistant: Epoxy grout for tiles can withstand stains from spills, dirt, and other materials, extending the life of your tiles’ pristine appearance.

- Waterproof: Because epoxy tile grout is waterproof, neither water nor mildew can grow on it. Because of this, it’s perfect for usage in damp environments like kitchens and bathrooms. Somany’s epoxy-based Ezy Grout cement provides tiles with a grout that is waterproof and resistant to chemicals.

- Easy to clean: Special cleaning or treatments are not needed for epoxy tile grout, which makes it incredibly easy to clean. Usually, a quick wash with soap and water will do.

- Cost-effective: One of the main factors contributing to epoxy tile grout’s appeal is its affordable pricing, which places it among the most economical tile adhesives.

- Versatile: Epoxy tile grout is useful for a range of surfaces, such as shower walls, worktops, floors, and backsplashes.

Epoxy grout for tiles comes in a range of colors that can be blended to match any tile color. Additionally, it comes in clear, which lets the tile’s original color shine through. How to maintain epoxy grout for tiles One kind of grout that is created with epoxy resin is epoxy tile grout. It is among the market’s most resilient grout varieties and is frequently utilized in commercial and industrial settings. Nevertheless, domestic applications can also make use of epoxy tile grout. It is simple to maintain and care for.

The following advice can be used to maintain epoxy tile grout: Regular cleaning of epoxy tile grout should be done with a mild soap and water solution. To stop mildew from growing, seal the grout if you plan to use it in a shower area. To avoid water damage, it’s critical to fix any chips or cracks in the epoxy tile grout as soon as you find them.

Conclusion

For those seeking a premium, long-lasting tile grout, epoxy may be the best choice. For many years to come, epoxy grout can offer a durable, impermeable seal that will maintain the excellent appearance of your tile. But before purchasing tile grout, it’s crucial to shop around since you should always choose a reliable brand that will live up to its claims. Your tiling projects can achieve a whole new level of expertise and complexity with the extensive choice of tile-laying options offered by CHEMAX.

Strengthening Foundations: A Crucial Step

Strengthening Foundations: A Crucial Step