Wall Putty Manufacturer India

10 Things to Look for Before Purchasing Wall Putty.

During construction, wall putty is an essential material that creates a level, smooth surface for painting and other wall finishes. But choosing the best wall putty product can be overwhelming given the variety that is offered on the market. This blog post will introduce the Wall Putty products from CHEMAX Chemicals and go over ten things to check for before buying wall putty.

– Wall putty type Wall putty comes in two primary varieties: cement-based and acrylic-based. While putty based on cement is less expensive but less long-lasting, putty based on acrylic is more costly but offers superior flexibility and strength.

– Time for drying Wall putty dries at different rates depending on the product. Select putty that dries quickly to save yourself time and trouble.

– Area of coverage Examine how much of the wall putty is covered. A large coverage area will guarantee that you use less putty overall, saving you money.

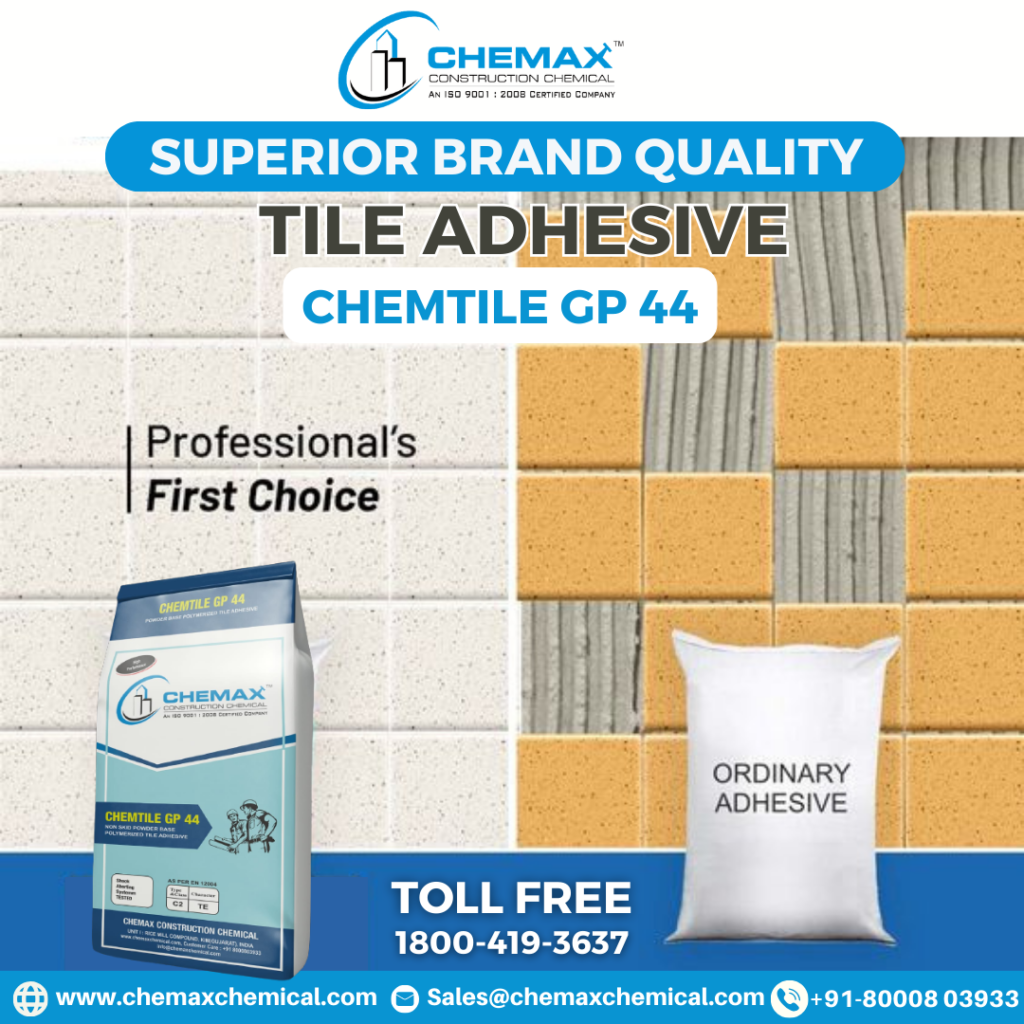

– Cohesion The putty’s adhesion strength is crucial because it dictates how well the material adheres to the wall surface. Seek putty with a high strength of adhesion to make sure it doesn’t come off easily.

– Resistance to water Water seepage through the wall surface is prevented by wall putty, so it should be water-resistant. Make sure the putty is resistant to water exposure and waterproof.

– Capability to fill cracks It should be possible for the putty to fill in surface cracks on walls. It guarantees that even after the putty is applied, the surface will stay smooth.

– Sanding proficiency After putty is applied, sanding it makes sure the surface is smooth and prepared for painting. Seek putty that sands easily and doesn’t leave any trace.

– Options for color There are several colors of wall putty, so it’s important to choose one that complements the paint color of your wall. Seek putty with a variety of color options.

-Reputation of the brand Select a brand that has a solid track record of providing high-quality goods and first-rate customer support. Before buying the brand’s products, check out the ratings and reviews.

-Price When choosing wall putty, price is an important consideration. Seek out a putty that is both affordable and provides good value.

In India, CHEMAX Chemicals is a well-known producer and distributor of wall putty products. Check out their selection of wall putty products here. Builders and contractors frequently choose their products because of their outstanding quality and longevity.

CHEMAX Cementitious materials such as wall putty are made with the purpose of leveling surfaces so they are ready for painting. This material is applied to various types of pores and cracks. To help you achieve a smooth and safe surface for painting, CHEMAX provides high-quality wall putty. Second, it is simple to apply various colors to the walls because of its color and other characteristics. Wall putty comes in a variety of colors and consistencies at Chemax. Wall putty is quite helpful when trying to smooth out uneven exterior or interior walls.

CHEMAX Wall Putty is a high-end acrylic-based putty with exceptional water resistance, high adhesion, and crack-filling capabilities. It dries fast and is simple to apply, which makes it the perfect material for building projects.

In conclusion, getting a smooth and even wall surface depends on choosing the proper wall putty. When making your purchase, take into account the previously mentioned factors and take into consideration CHEMAX Wall Putty products for high-quality and long-lasting solutions.

What factors lead to cracks?

What factors lead to cracks?