India’s Trusted Construction Chemical Manufacturer- CHEMAX

What Is Construction Chemicals ?

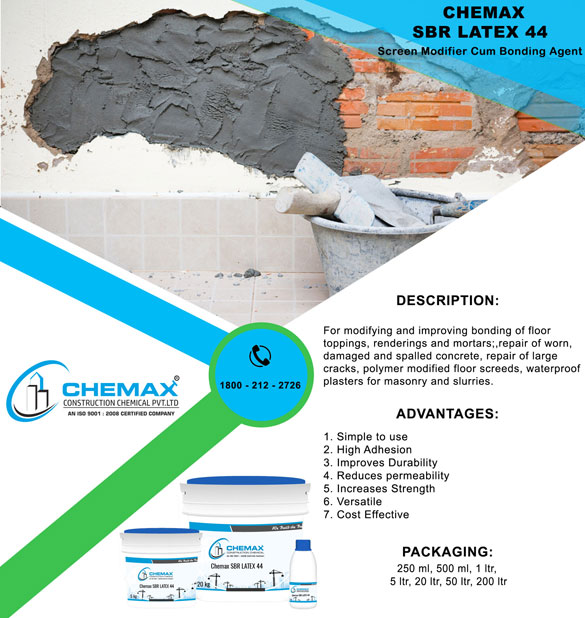

To improve the performance of buildings and building materials, a variety of chemicals are applied. We call these substances “construction chemicals.” By using these chemicals, one can increase the strength and longevity of concrete, stop metal structures from corroding, create waterproof surfaces, and offer fire protection. Construction chemicals are used to improve the qualities of materials used in construction, including steel, wood, concrete, and masonry. Concrete admixtures, for example, can be used to improve the value, toughness, and durability of concrete. Steel, concrete, and masonry surfaces can be protected from water damage by using waterproofing chemicals.

( Also Read: India’s Trusted Construction Chemical Manufacturer – CHEMAX )

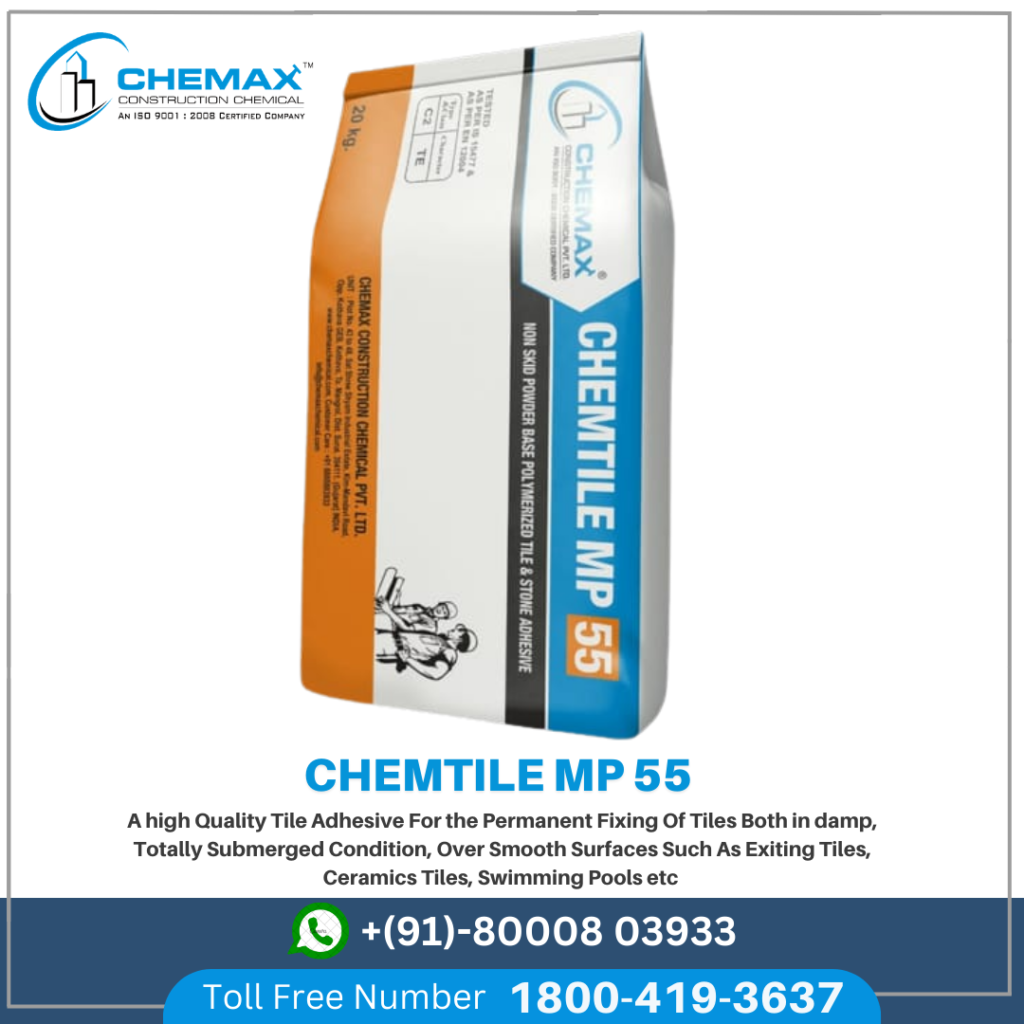

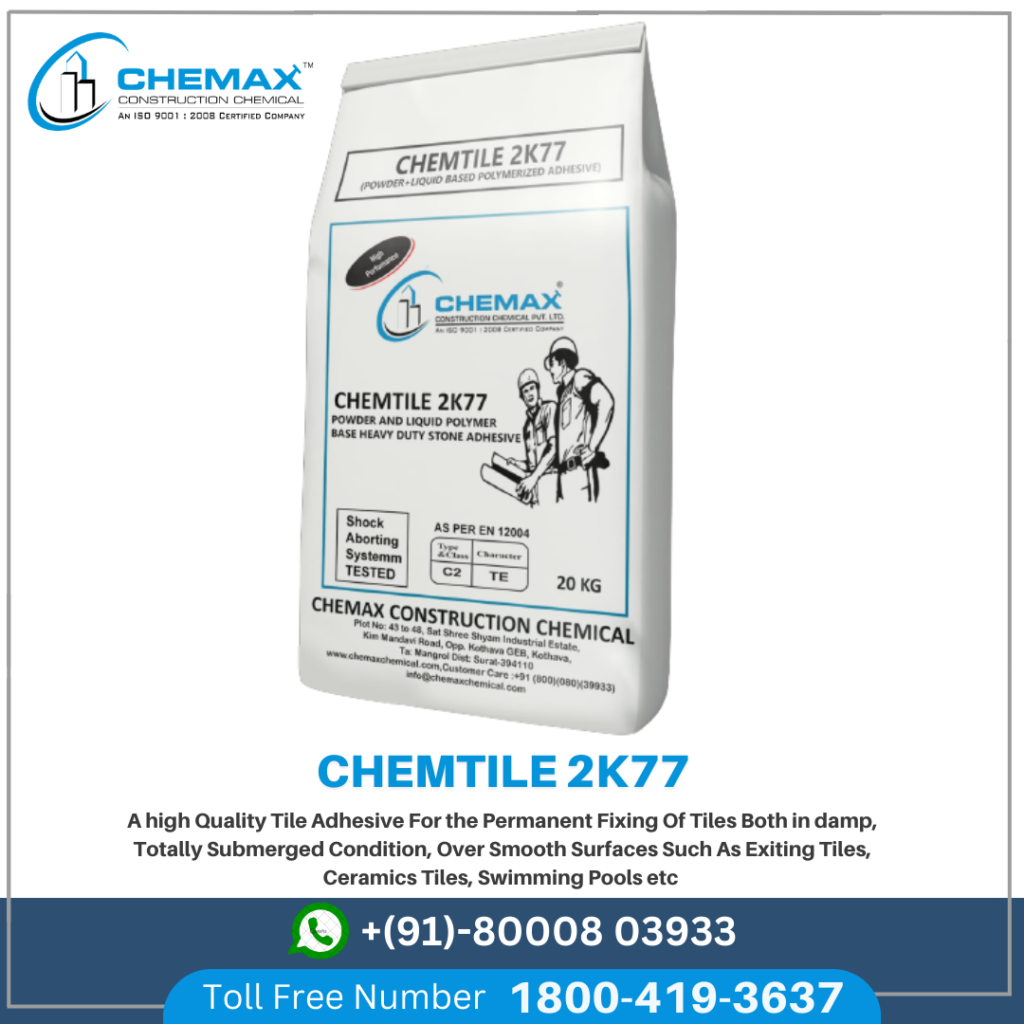

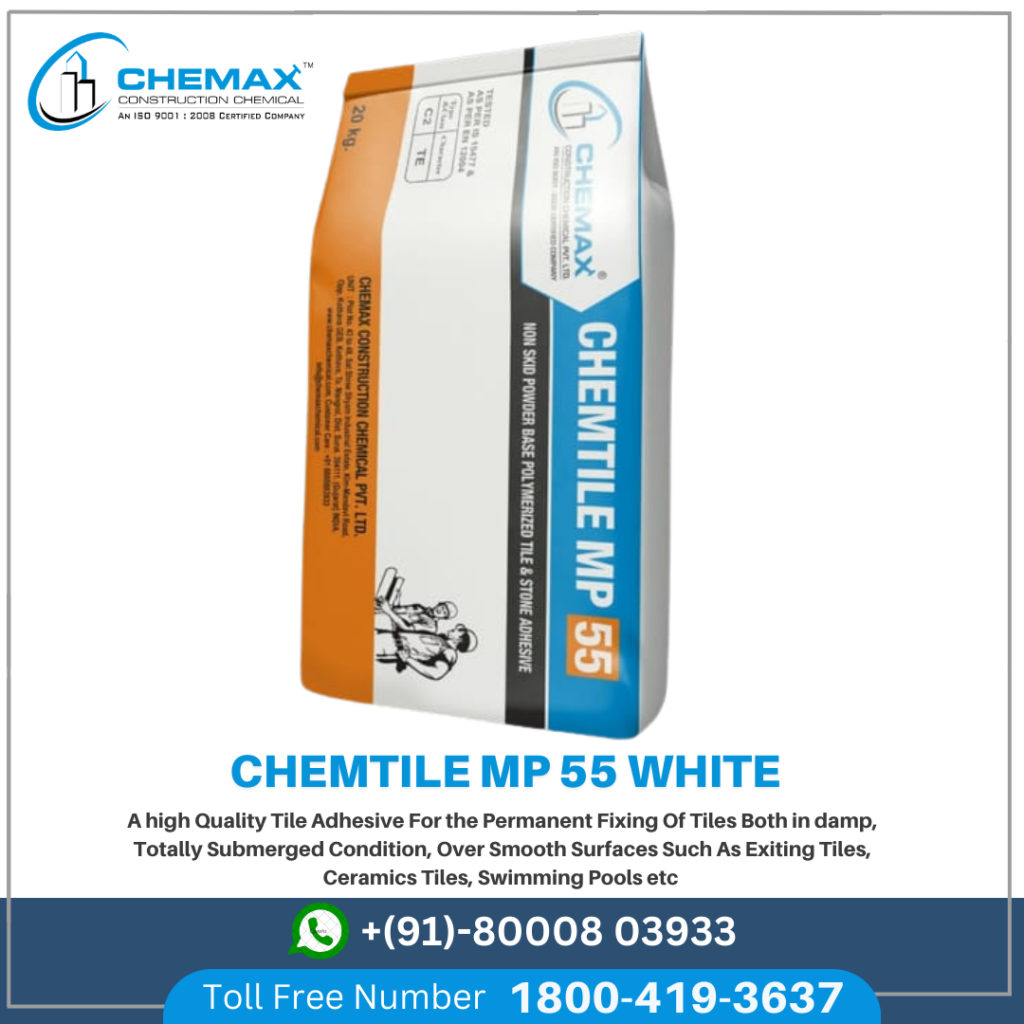

Among other things, common building chemicals include mixtures, adhesives, and waterproofing compounds. To make concrete, mortar, or grout more workable, durable, and strong, chemical additives are added. The compounds known as waterproofing agents keep materials used in construction, such as wood, masonry, and concrete, from getting wet.

Over the past few years, the worldwide construction industry has been growing steadily, and it is expected that this trend will continue in the anticipated amount of time. Numerous causes, such as population expansion, urbanization, an increase in the need for infrastructure, and technical improvements, can be attributed to the increase in building activity. One of the main reasons for the growth of the construction sector has been the rise in demand for homes and other types of constructions brought about by population growth. As more individuals relocate to metropolitan areas in quest of better job opportunities and higher living standards, urbanization is increasing.

Here, Chemax is India’s Trusted Brand For Construction Chemical Manufacturer in India.