Why Contractors Prefer Our Tile Adhesive?

The longevity and success of any project in the field of building and renovation greatly depend on the selection of materials. Builders and contractors are well aware that the materials they use can have a big influence on how their job turns out. Tile adhesive cement is one such essential item used in building and remodeling. We shall discuss the reasons why contractors vastly favor CHEMAX CONSTRUCTION CHEMICAL PVT LTD‘ tile glue over competing products in this blog.

Being a top producer and supplier of building supplies, we are renowned for our constant dedication to excellence and innovation. Although we offer a wide range of building products, our tile adhesive has been having a significant influence on the market.

No matter what kind of project you’re working on—residential or commercial—CHEMAX CONSTRUCTION CHEMICAL PVT LTD has the best wall tile adhesive to meet your needs. Let’s examine the main benefits and characteristics of this outstanding product to find out why contractors choose our tile glue.

Superb Bonding Power

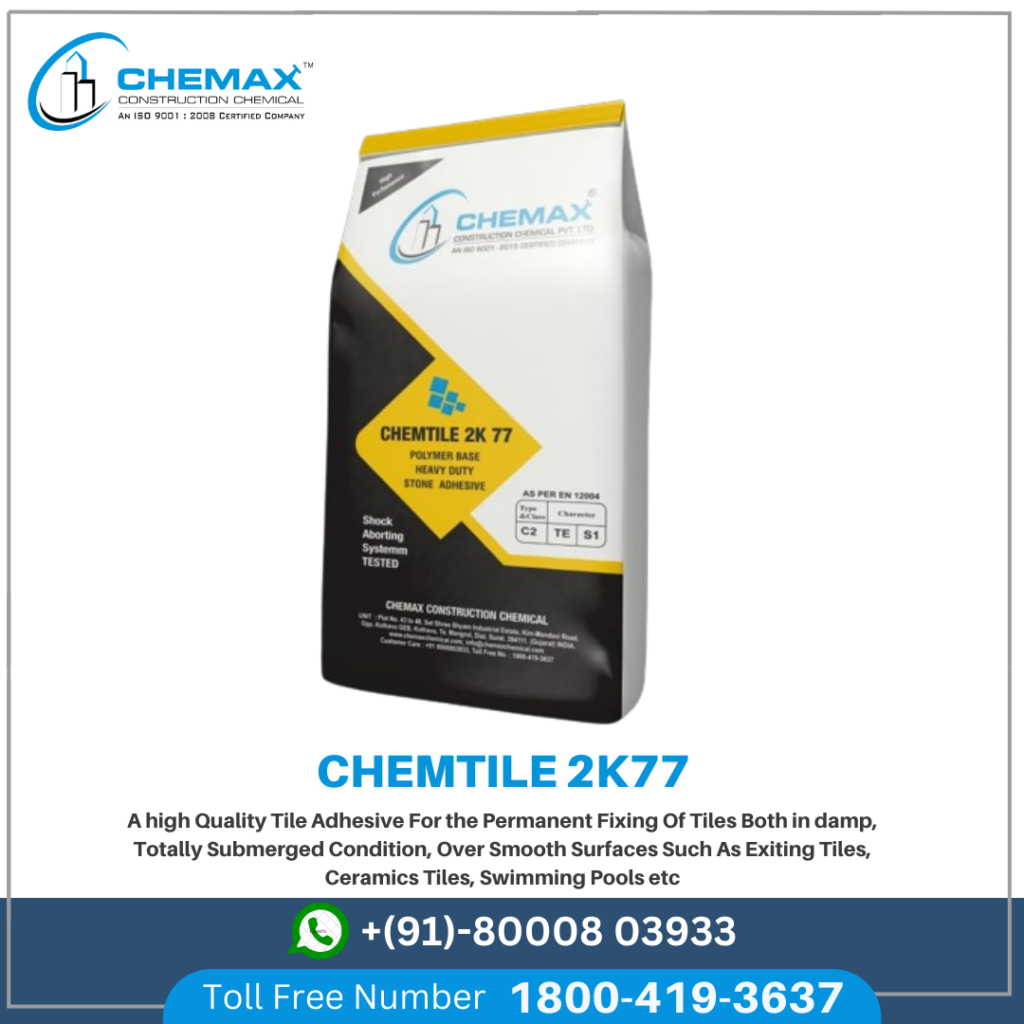

The bonding strength of tile adhesive is one of the most important considerations. In order to ensure lifespan and durability, tiles must be firmly attached to the surface. The tile adhesive from CHEMAX CONSTRUCTION CHEMICAL PVT LTD is well known for its remarkable bonding strength, which ensures that tiles will stay securely in place for many years. This resilience keeps tiles from coming loose or dislodging, which is especially important in places with a lot of foot activity or moisture exposure.

Adaptable Use

Contractors frequently take on a broad range of projects, each with its own special requirements and difficulties. We recognize the value of adaptability in building materials. Our chemical for tile glue is made to perform well in a variety of settings. You can rely on CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ tile adhesive to continuously provide exceptional performance whether you’re working on exterior or interior projects, on walls or floors, or with various tile kinds.

Application Simplicity

This property of our tile adhesive affects a construction project’s efficiency, cost-effectiveness, and overall quality; it’s not just a handy tool for contractors. The adhesive’s ability to spread smoothly, precisely place tiles, and reduce material waste is highly valued by contractors as it helps them save time and labor expenses. It contributes to a quicker project completion time by reducing errors and rework.

Water-Resistant

This is an essential component of the tile adhesive cement from CHEMAX CONSTRUCTION CHEMICAL PVT LTD that solves a number of issues with building projects. It guards against efflorescence, mold and mildew growth, and moisture damage. It guarantees tile installations’ longevity, making it appropriate for both indoor and outdoor uses. The project’s structural integrity is strengthened by preventing water damage, which also improves the tiled area’s aesthetic attractiveness. This function is highly valued by contractors since it not only streamlines the tiling process but also produces long-lasting, aesthetically pleasing installations that endure over time. Our water-resistant glue is a vital tool for producing tile installations that are dependable, long-lasting, and aesthetically pleasing.

Outstanding Sturdiness

CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ tile adhesive’s durability is a key component that solves a variety of issues with building projects. By withstanding impact and unfavorable weather conditions, preserving aesthetic appeal, and fending off wear and tear, it guarantees the resilience and lifespan of the tile installation. Our strong adhesive is very important to contractors because it prevents cracks and breakage, maintains structural integrity, and lowers maintenance and replacement costs. It is a crucial part of making tile installations that are long-lasting, durable, and aesthetically pleasing and that withstand the test of time. The best wall tile adhesive is CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ long-lasting glue, which is essential to building projects that are successful and long-lasting.

Time-Saving Treatment

Efficiency is crucial when it comes to building projects. Timely curing shortens project schedules, cuts downtime, lowers labor expenses, expedites work procedures, and helps contractors fulfill deadlines. It keeps the adhesive strength constant while improving flexibility and reducing the possibility of tile movement during the curing process. Construction projects benefit greatly from CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ time-efficient curing, which enables contractors to work more productively and confidently finish their projects on schedule and under budget. It is essential to designing tile installations that satisfy the needs of clients and contractors while being successful and economical.

A track record of success

The tile adhesive from CHEMAX CONSTRUCTION CHEMICAL PVT LTD has established a solid reputation thanks to a number of well-documented project successes. Numerous contractors have depended on our product and seen success with their tile jobs. The reason contractors favor CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ tile adhesive, which is the best wall tile adhesive, over alternative products is largely due to its track record of success.

Contractors strongly favor CHEMAX CONSTRUCTION CHEMICAL PVT LTD when it comes to tile adhesive. CHEMAX CONSTRUCTION CHEMICAL PVT LTD’ foundation is made up of outstanding bonding strength, adaptability, water resistance, durability, wide temperature tolerance, effective curing, minimal volatile organic compound emissions, and a track record of success. It’s easy to see why contractors rely on CHEMAX CONSTRUCTION CHEMICAL PVT LTD for tile adhesive.

Waterproofing Chemicals

Waterproofing Chemicals