Building Chemicals Supplier

To construct a sturdy, high-quality building, construction chemicals are required. Building chemicals are, in a way, the end products of the marriage of civil engineering, chemical engineering, metallurgy, and materials engineering. What are building chemicals? is a question that has an answer available.

Chemicals used in construction play a significant role in the business. It is extensively utilized in the building industry, which drives the economy and holds a growing market share in our nation. The quality and longevity of buildings are improved by the widespread use of building chemicals. Building chemical use will continue to rise with appropriate awareness of this industry.

What Are Construction Chemicals?

As the name suggests, construction chemicals are chemical substances that are employed in indoor, outdoor, and building construction tasks. These substances, which come from a specific area of the chemical industry, can be utilized in both new and ongoing building projects to strengthen and extend structures.

Although the cost of any construction project is increased by 2-5% due to construction chemicals, the advantages are numerous. Certain chemical products reduce the quantity of water and cement used in building. These substances provide chemical and physical characteristics for processes like phase transitions from liquid to solid or crosslinking. In order to promote the development of high-quality concrete and concrete performance, construction chemicals are necessary.

They also give additional protection against environmental risks and prolong the life of construction projects. These chemicals can be roughly categorized into five groups based on end-use applications.

- Concrete Additive Construction Chemicals

- Waterproofing Chemicals

- Flooring Compounds

- Repair and Rehabilitation Products

Concrete Additive Construction Chemicals

Concrete-added building chemicals are the first kind of building chemicals that spring to mind when someone asks “what are building chemicals?” A specific quantity of crushed rock, sand, and water are combined with concrete additive construction chemicals, a frequently used non-metallic building material, to create concrete. Cement or mortar additives are utilized to get better workability, increased strength, and finishing effects. Chemical additions are included into the mixture either right away or right after the mixing. It is practical and effective in this way. Concrete reinforced construction chemicals are mostly used for:

· In order to lower the price of producing concrete

· Modifying the characteristics of concrete that has hardened

· Maintaining the quality of concrete while it is being mixed, transported, placed, and cured

Chemicals for concrete reinforcement help produce durable, high-strength concrete that is employed in intricate architectural projects. It keeps the components of the concrete from separating and increases application time and convenience of use by allowing the concrete to flow. The query “What are the building chemicals that form the main subject of our article?” has an accurate response. The proper use of dosage and concreting techniques are essential for the successful use of such additives. In the plant or on the construction site, additives are added to concrete in liquid form that is ready for use. Additives typically make up less than 0.5% of the bulk of the cement. It is believed that one or more types of additives are included in 50% of the concrete produced in India today. At least 70% of the created concrete comprises a water-reducing mixture, and volatile materials are used to produce 80% of ready-mixed concrete.

Waterproofing Chemicals

Waterproofing chemicals are also brought up in relation to the subject of what constitutes building chemicals in the construction process. Now is the time to select the waterproofing materials that will best suit your requirements. With products like expanded polyethylene, waterproof concrete, polypropylene cement-based composites, elastomeric polyurethane, polysulfide sealants, polyurethane systems, water-repellent materials, and butyl and acrylic sealants, it is appropriate for a variety of end-use water applications.

Waterproof compounds can be sprayed, dipped, sprayed under low pressure, or utilized in slurry, liquid, or two-component processes on surface coating forms. These goods can be made of rubber polymers, clay, modified asphalt, or urethane. Water leaks are avoided via the construction of waterproof components. These substances or membranes, when used outside of a fundamental system, can be incredibly efficient. Getting professional advice on the best waterproofing chemicals for building and how to use them will always produce the desired results.

Flooring Compounds

Construction chemicals can be utilized from the ceiling to the floor of a structure during construction. Flooring chemicals are included in this. As a result, it is essential to examine the issue of what constitutes flooring compounds—a term used to refer to building chemicals. The most prevalent flooring compounds utilized in construction today are based on epoxy and polyurethane. Industrial flooring compounds are used to strengthen damaged floors, improve the floor’s visual attractiveness, and address a variety of industrial needs, including abrasion, load effect, chemical attack, and moisture penetration. Additionally, they serve to impart particular qualities including fire resistance, static resistance, shear resistance, and antibacterial qualities.

Repair and Reinforcement Products

Building chemicals are beginning to show up in the fields of reinforcement and repair as well as new building. Restoration and revitalization The market for reinforcement remains unexplored and undeveloped. However, for individuals who are engaged in this sector, the topic of what constitutes building chemicals is becoming more and more important.

Enhancing energy-efficient structures and incorporating new features or technology into outdated systems is known as reinforcement. Reinforcement refers to the process of rebuilding damaged building elements. These goods include moisture-insensitive epoxies, polyester and epoxy-based resin mortars, concrete floor repair solutions, cement-based repair mortars, synthetic adhesives, rust removers, and corrosion inhibitors. The three primary techniques are FRP coating, steel jacketing, and concrete coating. Such techniques can be applied to the renovation of old and historical buildings. The topic of what constitutes building chemicals comes up during the renovation process.

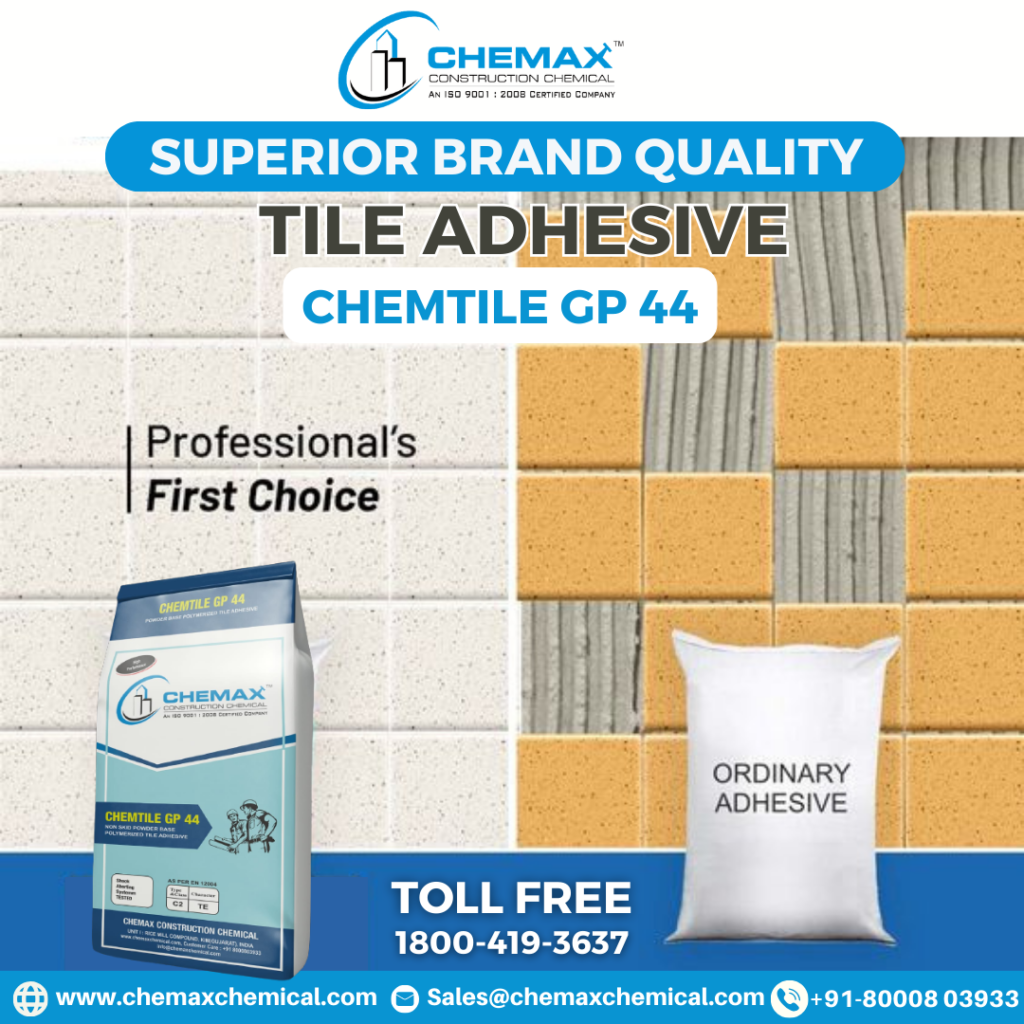

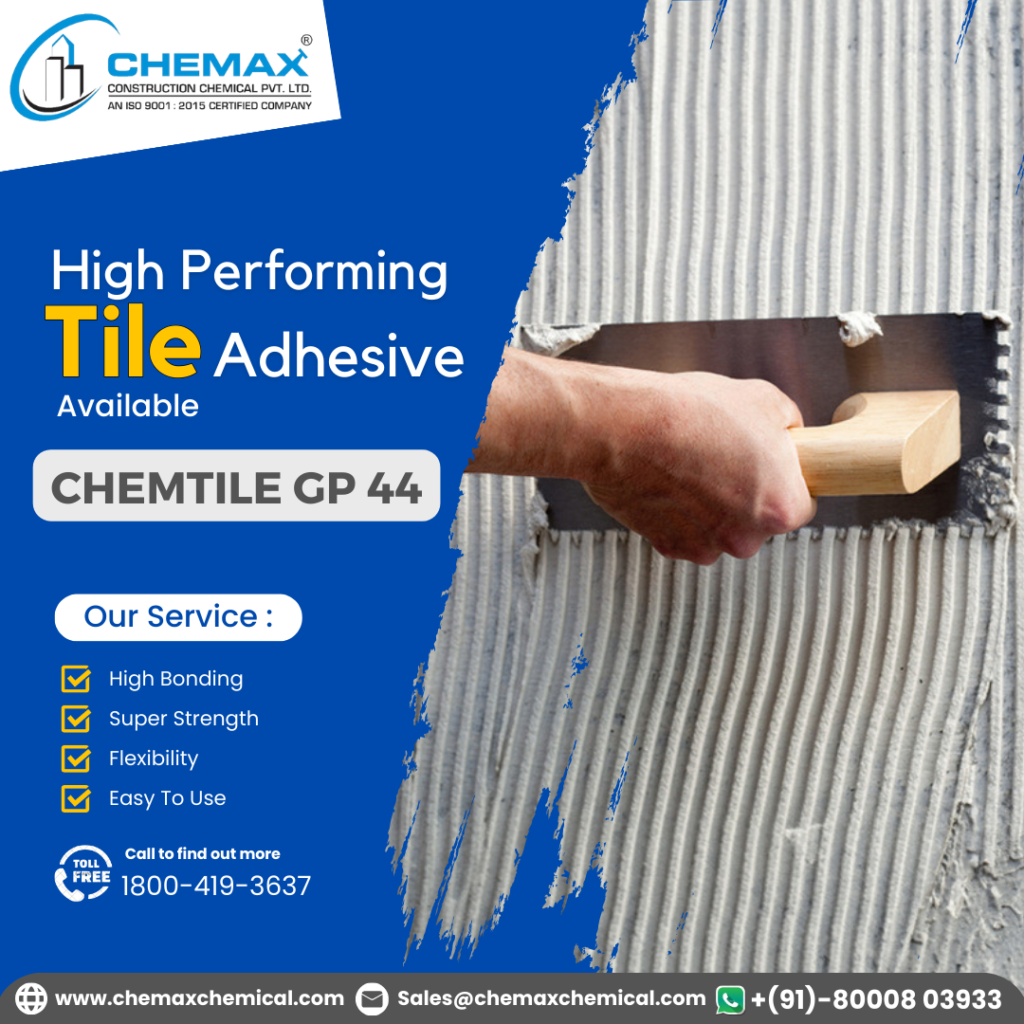

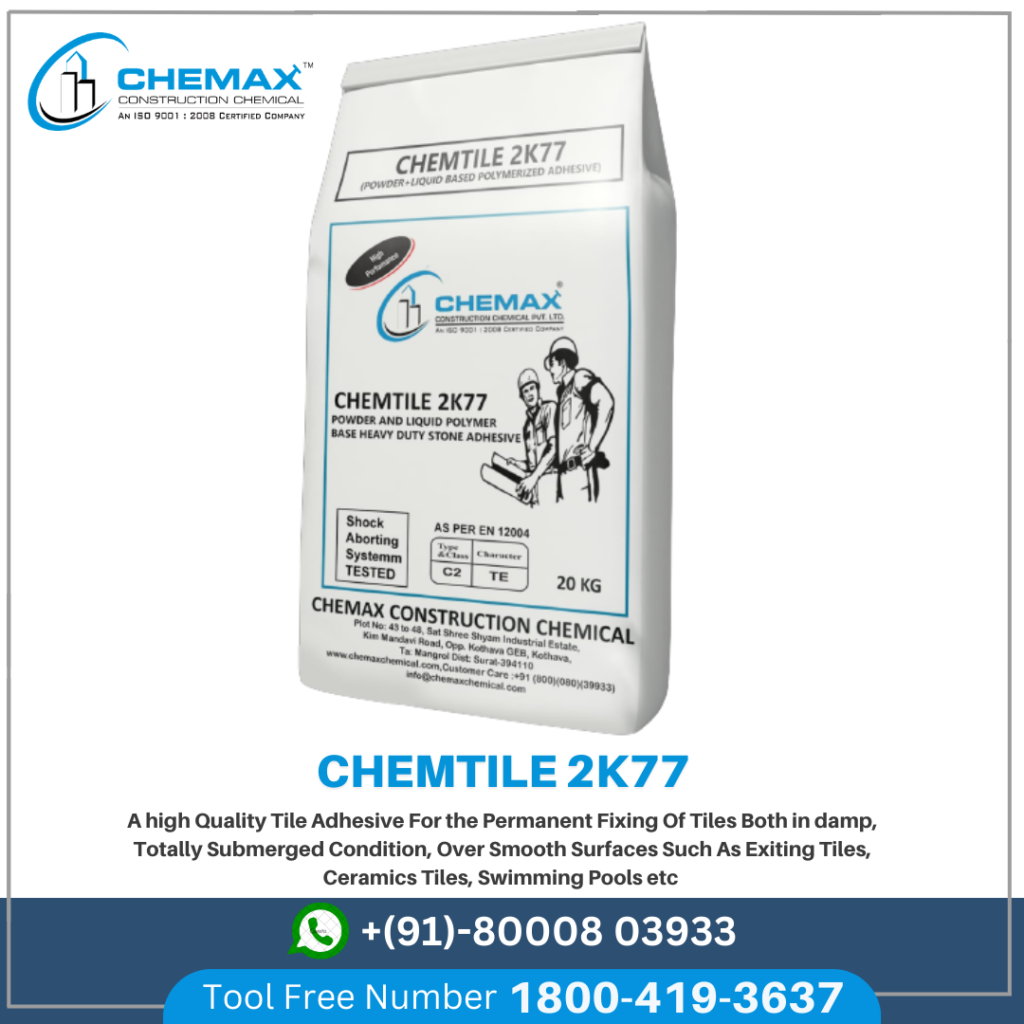

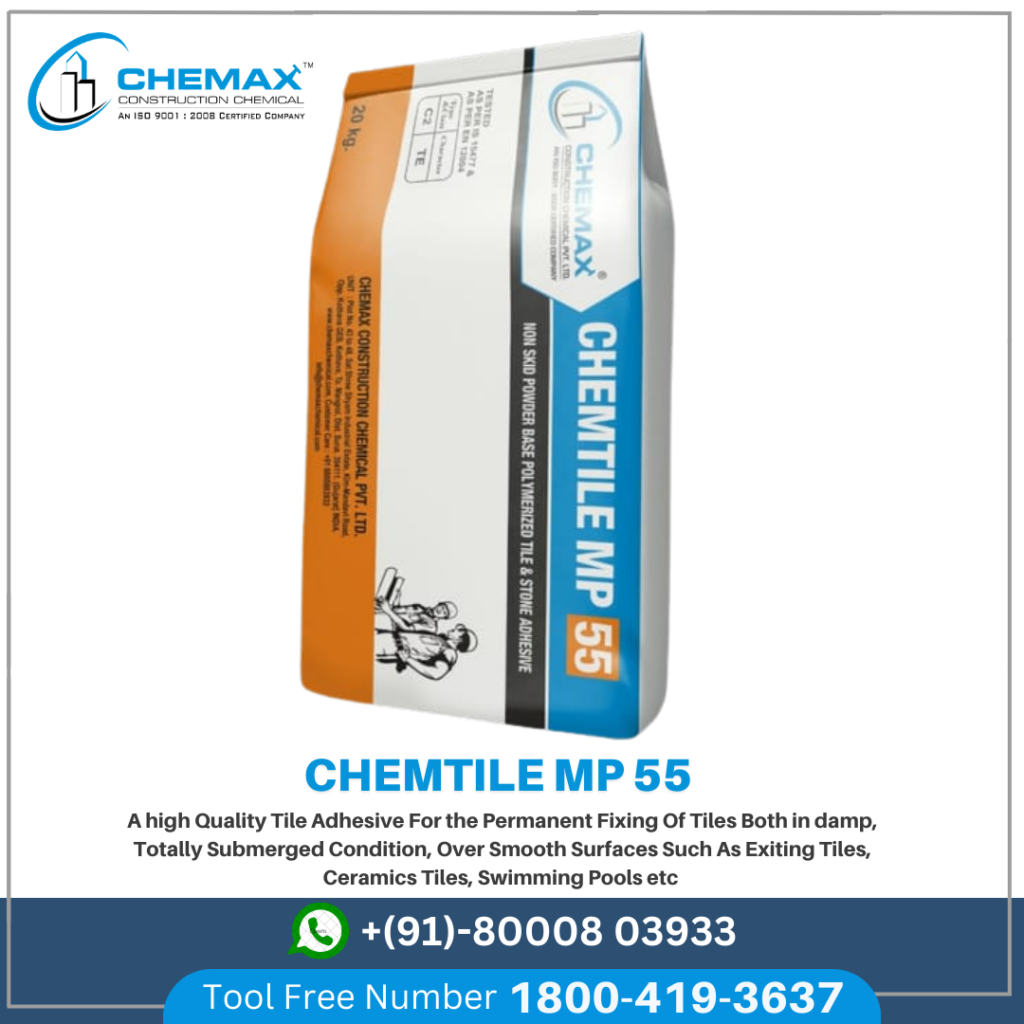

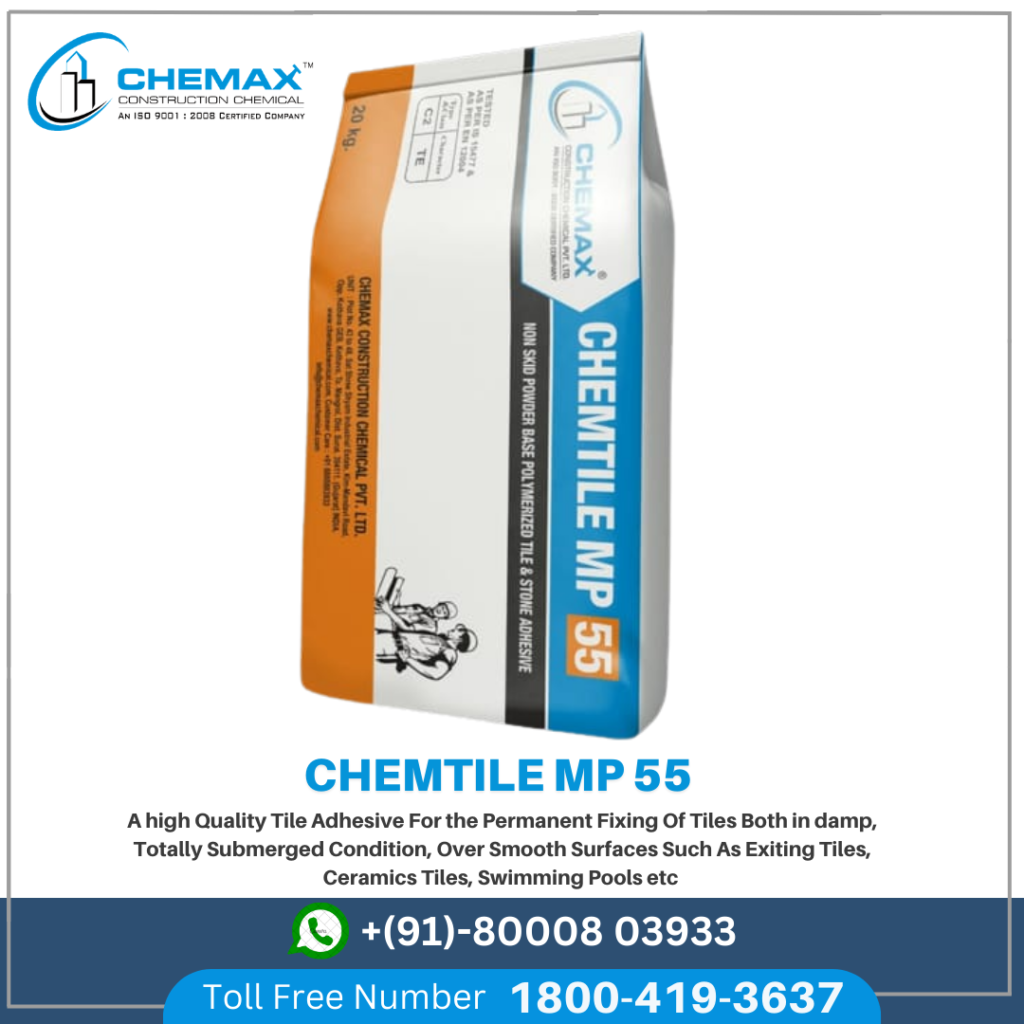

CHEMAX is renowned for providing an extensive selection of high-quality building chemicals, including adhesives, grouts, wall putti, waterproofing, concrete admixtures, and flooring solutions.

Because of our experience, cutting-edge facilities, and unwavering commitment to innovation, we have consistently provided best-in-class construction products to our global customers. Both residential and commercial construction make extensive use of our solutions. We can provide you with engineering and construction chemicals for your next large project, whether you’re starting from scratch or need them for repair and rehabilitation.