View Large

View Large

CX FLEXIBOND 2C

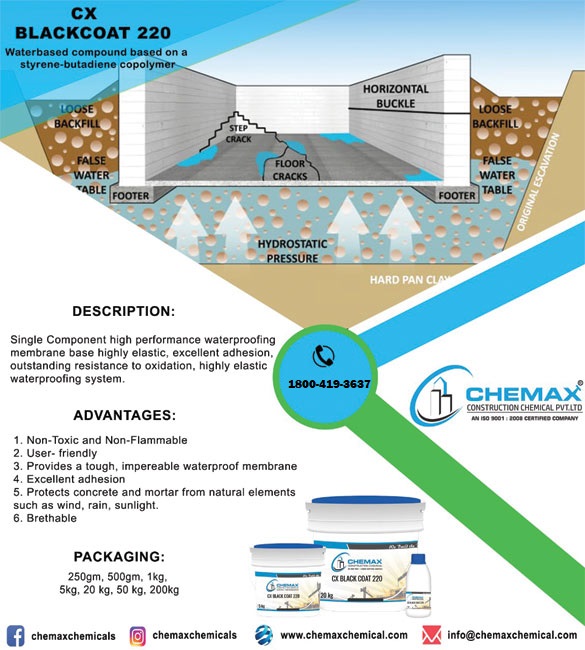

CX FLEXIBOND 2C is a two component acrylic polymer modified elastomeric waterproofing membrane which consists of CX FLEXIBOND 2C powder and FLEXIBOND BB liquid acrylic emulsion. It requires only clean fresh water on site mix when mixed in the proper proportions; an easily brushable coating is produced.

Uses :

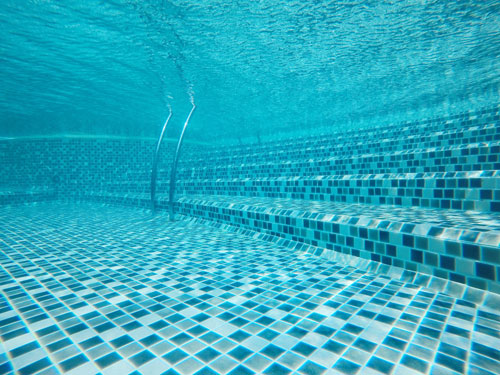

1.CX FLEXIBOND 2C provides a seamless, waterproof coating suitable for use in water tanks, reservoirs, swimming pools, roofs and to ensure water tightness.

2.CX FLEXIBOND 2C effectively protects against concrete decay providing a long lasting barrier to waterborne corrosive salts and atmos

CX FLEXIBOND 2C provides an elastomeric protective waterproof coating and is shown to resist positive hydrostatic pressure upto 7 meter head. The degree of resistance of CX FLEXIBOND 2C to water under pressure depends on the coating thickness.

Areas subjected to moderate and heavy loads/hydrostatic pressure. Minimum 2mm thickness coating is recommended with screed above.

| properties | Values |

| Pot life At 20C | 1 hour |

| Pot life At 35C | 20 minutes |

| Mixed Density | 1.90kg/liter (brush able Consistency) |

| Tensile strength | 2 N/mm2 (at 1.5mm Thickness) |

| Colors | Grey and white |

| Application temperature | Not less than 10C |

| Toxicity | Non-toxic |

| Adhesion to concrete | >1N/mm2 |