View Large

View Large

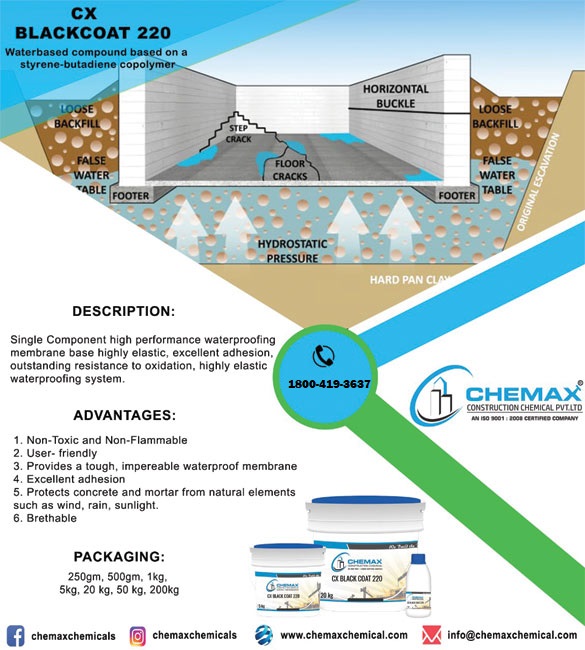

CX WATERSEAL WH

CX WATERSEAL WH is formulated to be mixed with cement on site or simply brush applied over concrete or masonry surfaces to provide an effective waterproof membrane.

Uses : CX WATERSEAL WH provides an effective and economical method of waterproofing to concrete and masonry surfaces, by mixing with cement and application by brush.

Advantages

Properties

| properties | Values |

| Water absorption | 1% maximum |

| Pot life at 300C | 30 minutes |

| Application temperature | Not less than 100C |

| Toxicity | Non-toxic |

| Bond strength to concrete | Approx. 1 N/mm2 |

Application